Silver Fabrication

Although students in the silver classes must have their own individual tools, the SDMG silver shop is equipped with larger pieces of equipment such as torches, drill press and a buffing station.

Silver Fabrication

Students in the silver classes work on a variety of projects, learning to make rings,

pendants, bracelets and other articles of jewelry.

Casting

The casting room contains everything students need for casting projects,

including lost wax casting and mold-making.

Faceting

Learning to cut faceted gems takes practice. A good instructor can provide

many useful tips to make the learning curve less steep.

The main shop area contains all of the tools students need for making cabochons

The shop has two large slab saws, with 22" and 18" diamond blades, respectively,

for cutting slabs from rough material, and a trim saw that students use

to cut the slabs into the rough outline of cabochon shapes.

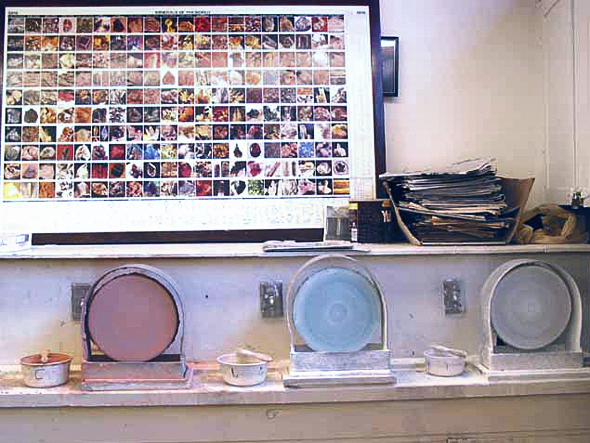

Main Shop: Dopping, Grinding, Sanding

After the student has cut the rough shape of the cabochon out of the slab (foreground inset), the stone is brought to the dopping station and attached to a wooden dowel using a special "dopping" wax.

When the stone has been attached to a dop stick, it can be ground to shape on the diamond grinding wheels (background) and then given its finished shape on the sanding wheels (background right).